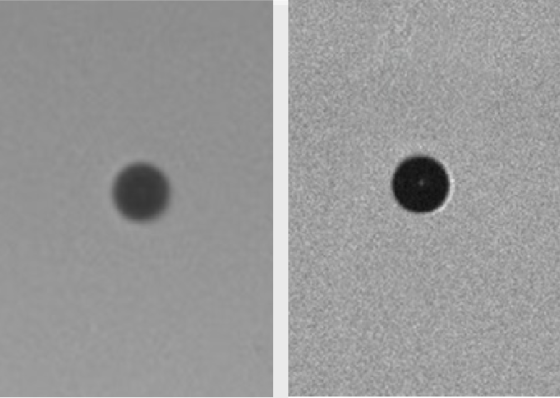

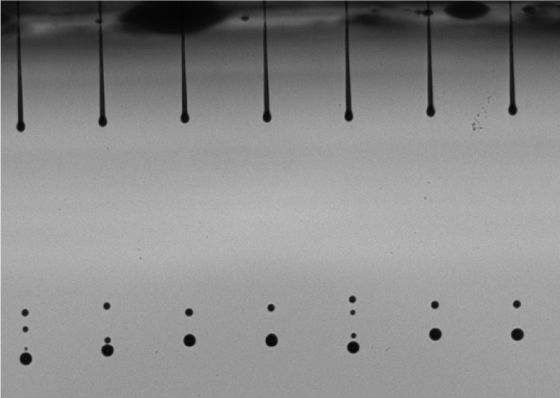

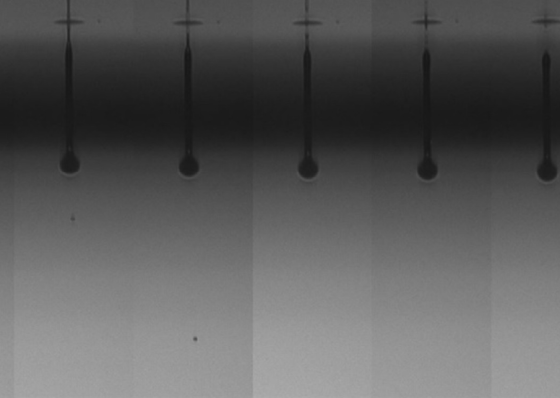

Meteor’s advanced DropWatcher Optics enable more precise visualisation and measurement of ink droplets, enabling users to analyse and improve print quality with greater confidence and control.

Building on the proven synchronised strobe and long-exposure imaging approach of earlier Meteor DropWatchers, the new system introduces enhanced optical and timing technologies that capture sharper, more detailed images of individual droplets. This allows accurate measurement of drop volume and a deeper understanding of dynamic behaviours such as ligament breakup, meniscus oscillation, and mist generation. This advancement provides a new level of measurement precision and analytical capability.